In this production cycle, a bracket measuring 600x700x220+220 with a capacity of 50 brackets/hour is used. Maximum withdrawal for each single casting is 50,000 kg of molten metal. The peculiarity of this process is the high technology adopted, linked to the high professionalism of the operators.

METAL TREATMENT AND CASTING

The molten metal in crucible melting furnaces is transferred to waiting electric furnaces and properly treated and controlled (vacuum test to determine alloy density and chemical analysis). The casting phase is managed by a fully automated robot that ensures continuity throughout the production batch with very narrow range levels.

MIXER

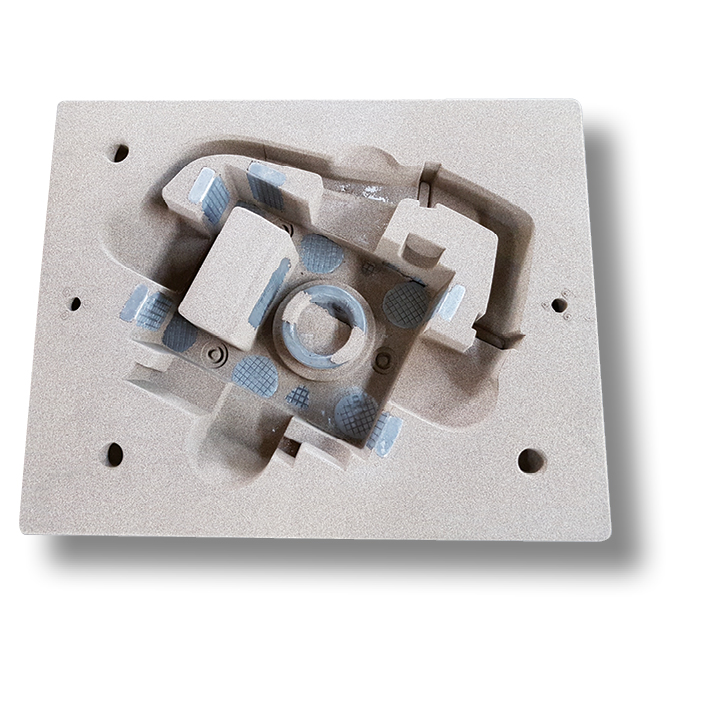

Plant for forming with self-hardening resin for large and geometrically complex castings.

Chemical Molding

MOLTING IN SAND AND RESIN WITH INSERTION OF CAST IRON COOLERS AND ISOTHERMAL SLEEVES

AUTOMATIC PLANT

The automatic plant consists of an 8-station carousel capable of being equipped with maximum-sized formwork models