MEASURING INSTRUMENTS LABORATORY

FGT, using its own measuring instruments and relying on qualified external laboratories, is able to provide a 3.1 Certificate, also guaranteeing the traceability of the produced batches. Upon customer request, visual inspections and liquid penetrant tests are carried out.

RADIOSCOPIC INSPECTION

FGT has a facility for radioscopic inspection of castings with acquisition and processing of digital images supported by an operator with non-destructive testing (NDT) level 2 training according to SNT TC1A Personnel Qualification and Certification in Nondestructive Testing.

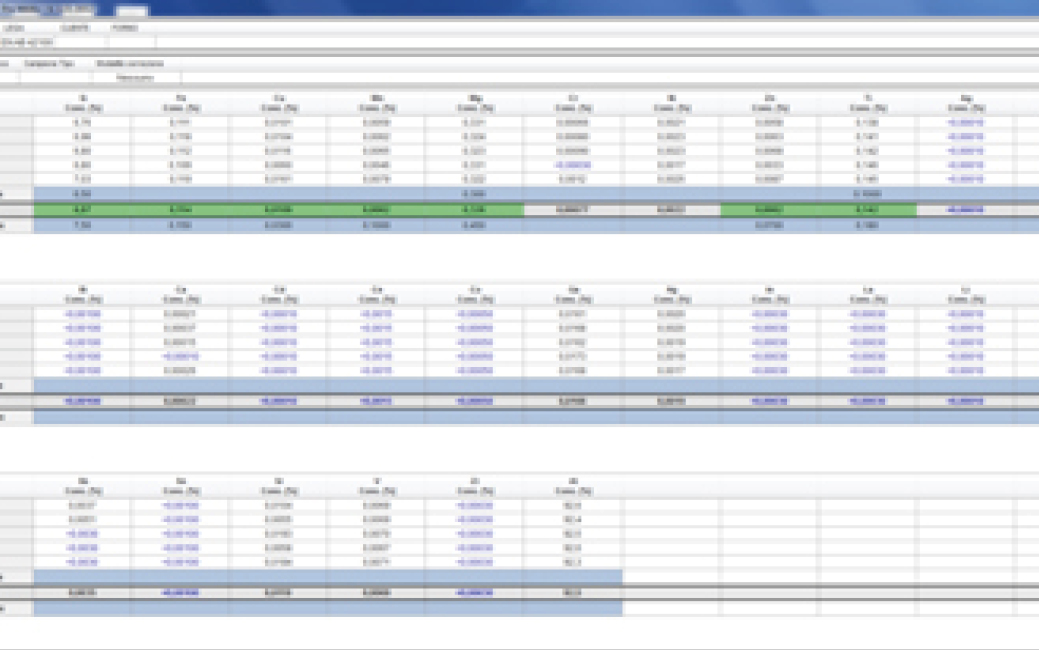

To ensure the quality and traceability of the produced batches, FGT employs the following measuring tools in its internal laboratory:

Spectrometer – Spectro MAXx6

Vacuum sample preparation facility

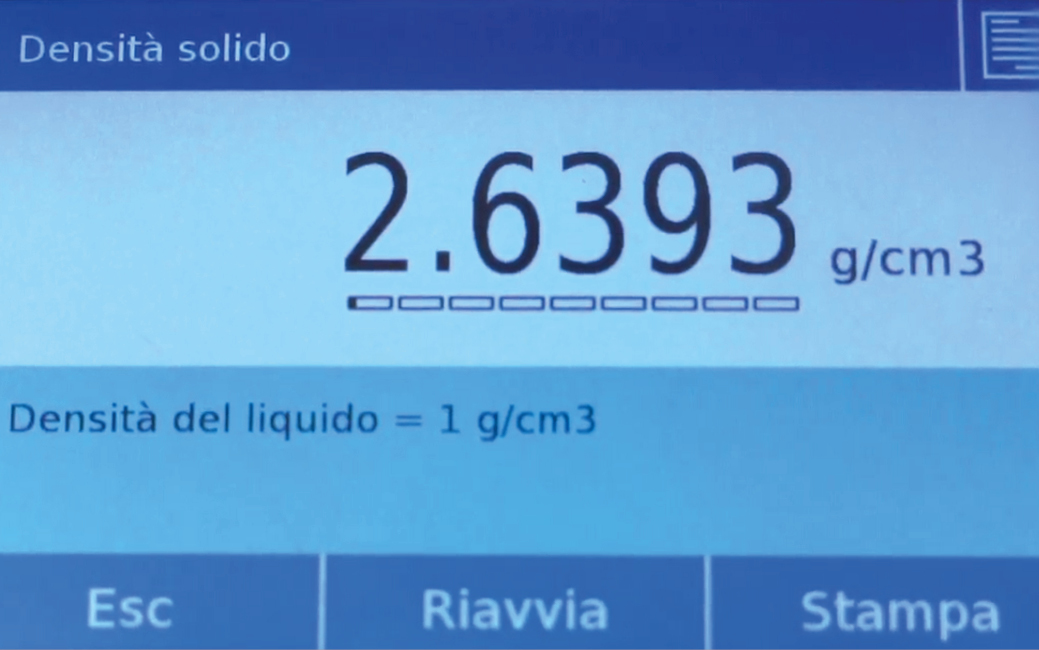

Density control balance for M5-IDENS alloy

X-ray machine – Bosello MAX 80-150

Certified thermocouple for temperature control

Sample polisher

Durometer

Extensometer

Set of calipers